Packaging.

We are on our way of reducing packaging waste and promoting sustainable packaging. Before we used to put an original SINOBI box in a shipping box. We have decided not to use the original cardboard boxes, but only shipping boxes and shoe bags.

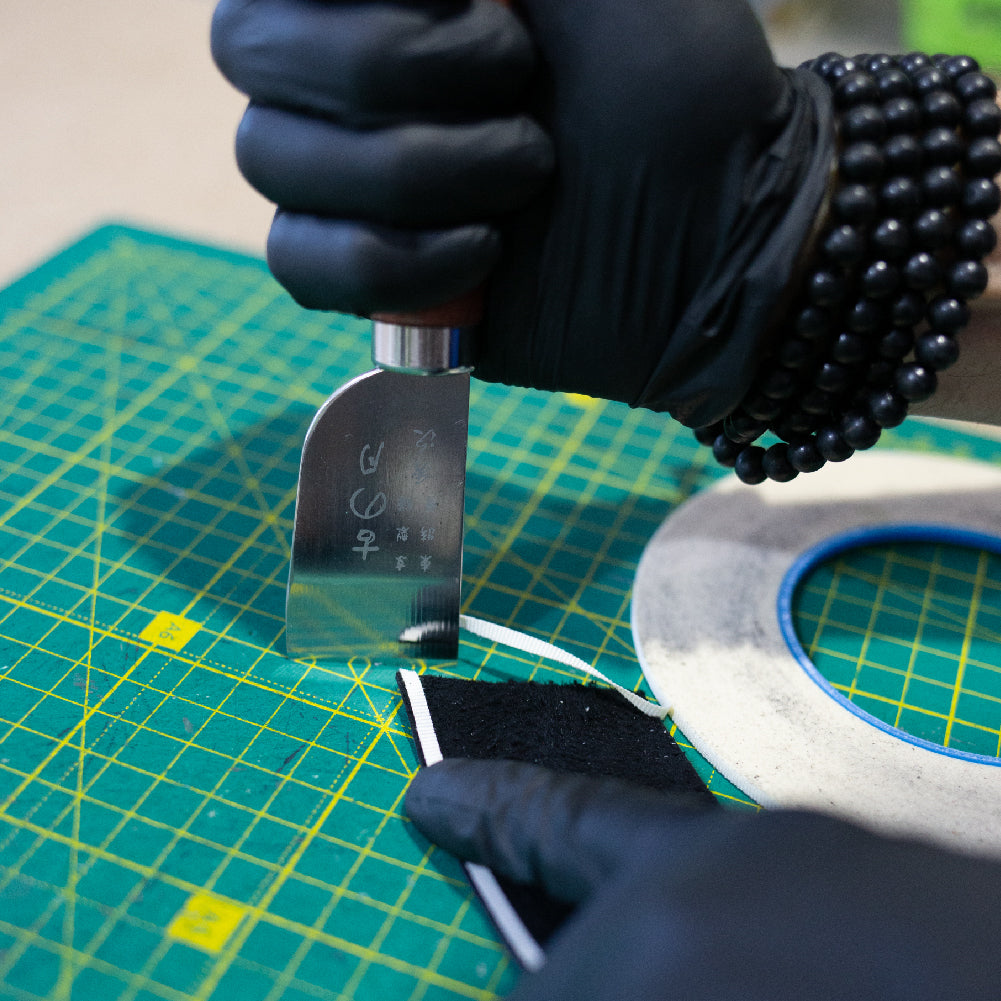

Leather manufacturing process results in many leather pieces and shreds leftovers. Instead of throwing away or utilizing them, we decided to give a second life to leather wastes by turning them into pockets for our shoe bags that our customers can use further on.

This makes every pocket on our shoe bags unique, as it is composed of different leather pieces.

Logistics.

SINOBI is the first Ukrainian fashion company who became a part of the DHL «Go-Green» programme. We also prefer to use electro cars when moving around or delivering.